Rapid Delivery for Welding Excavator Bucket Teeth - 1U3302 1U3352 standard Rock forging bucket tooth for excavator spare parts – Aili

Rapid Delivery for Welding Excavator Bucket Teeth - 1U3302 1U3352 standard Rock forging bucket tooth for excavator spare parts – Aili Detail:

Product Detail:

1. Product Parameter/specification of 1U3302 1U3352 standard Rock forging bucket tooth:

| Part no.: | 1U3302 1U3352 1U3302RC 1U3352RC |

| Color: | Yellow/Grey |

| Material: | Round Alloy Steel |

| Hardness HRC: | 49-52 |

| Impact Toughness: | ≧18 |

| Tensile Strength: | ≧1372 |

| Elongation: | ≧1.5% |

2. Production Processes of 1U3302 1U3352 standard Rock forging bucket tooth:

Forging production line: Mold processing-high frequency heating-forging-heat treatment-painting.

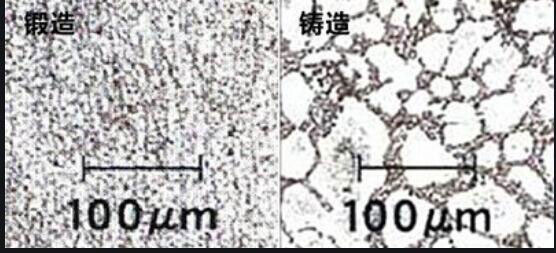

3. Comparing Forging bucket tooth with casting bucket tooth:

Forging bucket tooth advantages:

1)Product interior structure with higher density ,not

have inner gas holes

2)Higher Impact Toughness

3)More stable Hardness

4)The product surface is perfect, completely free of

pores and defects, close to the surface of the

machined product

5)Mechanical automation produce and reduce the

quality problems caused by human factors and

labour cost.

4. Customers feedback:

In the mine test of Aili forging bucket teeth, customer feedback is very good, forging teeth have the advantages of good wear resistance, high toughness and long working life.

Product detail pictures:

Related Product Guide:

The difference between forging and casting

To meet the customers' over-expected pleasure , now we have our potent staff to offer our greatest general service which includes internet marketing, sales, planning, output, quality controlling, packing, warehousing and logistics for Rapid Delivery for Welding Excavator Bucket Teeth - 1U3302 1U3352 standard Rock forging bucket tooth for excavator spare parts – Aili , The product will supply to all over the world, such as: Bhutan, Kenya, Philadelphia, In the future, we promise to keep offer the high quality and more cost-effective products, the more efficient after sales service to our all customers all over the world for the common development and the higher benefit.

COMPANY OVERVIEW

Located in the beautiful Yichun City Jiangxi province, near in Ningbo port and shanghai port. Aili is a modern enterprise specialized in the R&D, manufacture and sales of precision casting parts. Aili established in 1980,we already have 40years casting experience .Covering an area of 110,000 sqm; have more than 200 staffs; Annual production capacity is 24,000 tons; Export to all of world more than 100 countries; Annual Sales Volume more than 30 million dollars among it ,60% is overseas market, 40% is domestic market.

Our company has advanced investment casting line, forging line, environment friendly continu-ous heat treatment furnace, as well as the top testing equip-ment in this industry. Now we mainly supply all kinds of excavator bucket, bucke tteeth & adapters and some precision casting &forging products, like:Teeth,Adapter,side cutter,cutting edge,bucket,protector,pin,retainer,bolt,nut ect We can develop and design all kinds of mould, precisioncasting mould and forging upon special request.

Trade mark: Aili

AIli possessing precisionfoundry factory, Ceramics Casting factory,Automatic production line we also can call Static pressure modeling line (SPML )Aili is also the only manufacturer in China that use static pressure line to produce tooth and adapter,precision forging factory, mold and CNCmachining center  TESTING EQUIPMENT

TESTING EQUIPMENT

We have most advanced physicochemical inspection equip-ment including: Optical Spectrum Analyzer which inspect and analyze chemical composition, Metallography microscope which testing the Inspection Machinery:We have 6 sets Wire cutting machine,Improve the speed of mechanical performance test Rockwell Hardness Tester and Brinell hardness tester to test the block,These two machines can provide customers with different reference hardness requirements. our Impact Testing Instrument ,Tensile testing machine to test the thoughness and tension.

Advantages

1.Cooperating with world famous brands ,

1.to be the supplier of VOLVO since 2014

2. to be the supplier of the world’s first brand of loader SDLG in 2018 .

2.Certificate of Design Patent ,we got this in 2016. 3.Aili is the only company in China that can independently develop chemical composition materials. INDEPENDENT RESEARCH AND DEVEL OPMENT, Our company has independent R & D department, whichspecialized in developing new products.

4 We have got 8 invention patents Meanwhile our company has been confimedas National Hi-tech enterprise.

5.warehouse with more than 20 thousand spuare meters , can stock about 3000 tons products in it. Export goods are all packed with MDF wooden case and we will put a water-proof plastic inside to prevent rust during shipment on the sea.

112我瞧瞧

Q1. Sample

—- sample is free,but you need to pay the freight.

Q2. Address

—- Factory Address: NO.1, CENTURY AVENUE,INDUSTRIAL PARK, JING’AN COUNTY, YICHUN CITY,JIANGXI P.R., CHINA

Q3. Product

—- Teeth,Adapter,side cutter,cutting edge,bucket,protector,pin,retainer,bolt,nut ect

Q4: Paymment Terms

—- T/T

Q5. Logo

—- No logo/Aili/Customized.

Q6. Lead Time

—- Products in stock: immediately; Regular products: 20 days.

Q7. Aftermarket

—- We guarantee the product quality. If there is any problem, we have a professional service team to reply within 24 hours and provide solutions within 3 days.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.