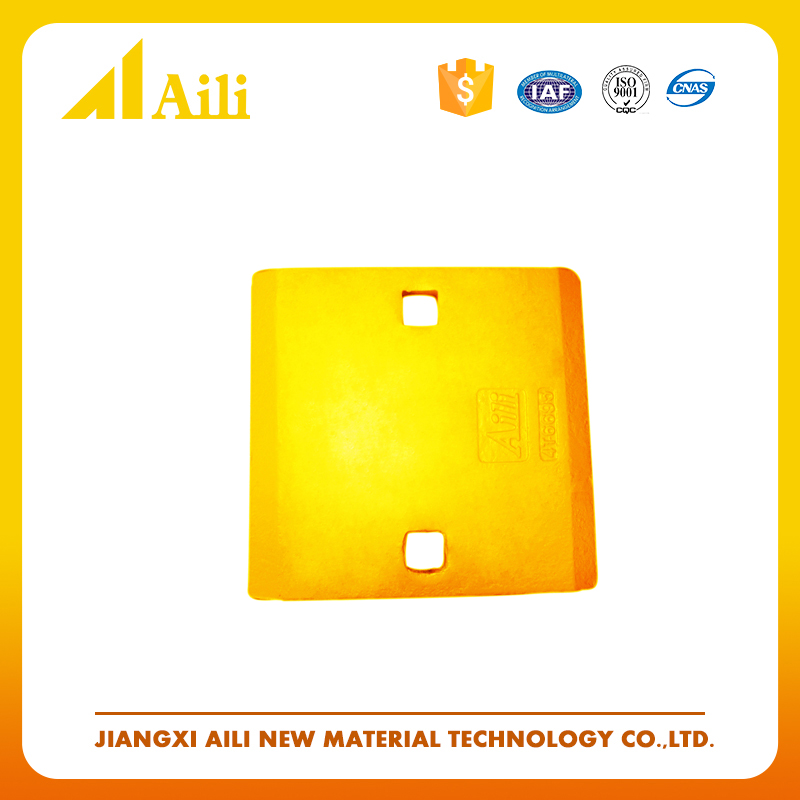

4T6695 4T-6695 Wheel Loader Bucket Cutting Edge Segment

4T6695 4T-6695 Wheel Loader Bucket Cutting Edge Segment, Caterpillar style Wheel-Type Loader end cutting edge blades, Segment Edge Protection 25mm,double beveled reversible bucket bolt-on segments, Replacement EDGE- SEGMENT for Caterpillar, CAT GET spare parts China Factory.

Caterpillar style bolt on segment for a Caterpillar Front End Loader. This is a double beveled reversible bucket segment that is 1′thick, 11′wide and 10.4375″in length. It takes 2 of a 1′X2 3/4″(100X275) plow bolt and 2 ofa 1′(100 HEX NUT) hex nut. The bolt hole spacing is 7.68′from center to center of the bolt holes, and 1.38′when measured from the edge of the bucket cutting edge to the center of the first hole.

Quality aftermarket G.E.T. (bucket teeth) for Caterpillar (CAT), JCB, Bobcat, Takeuchi, John Deere, Case,Komatsu, Kubota and many others indluding manufacturers such as Custom, Hensley, H&L for all your backhoe, loader, skid steer, grader, scraper and excavator bucket tooth (teeth) needs.

Wheel Loader Bucket Segment Edges fts Caterpillar 4T-6695, 4T6695 Loader Segment Edge Protection fts Caterillar, 4T6699 4T-6699 Caterpillar style Bolt-On Segment, Track-Type Loader Cutting Edge Segment 4T6693 4T-6693.

Cat bolt-on cutting edge segment have moderate impact resistance to allow them to perform across a variety of applications boosting your machines versatility. They are designed to protect the bottom of you base edge lip between adapters and to increase bucket capacity, and reduce downtime by maintaining a long wear.4T6699 4T-6699 Replacement Caterpillar style Segment Edge.

All Aili G.E.T Parts are produced to the highest industry standard to ensure our customers receive optimum life form our G.E.T spare parts.

Advantages:

1. Quality guarantee and control

2. Technical support

3. Factory with more than 40years

4. Three different production processess, including four different Forging production line.

5. Original supplier of World famous brand.

6. Complete Testing machines

Chemical Component: Please contact with our sales to know more details.

Aili manufacture has 4 big workshops, factory is covering an area of 110,000sqm,has more than 300 staffs, and complete production machines and testing finances. Aili current has three production line, one is Ceremic Wax lost, and the second one is Full automatic production line, and the third one is foring teeth, which has better Mechanical properties, better wear-resistance and longer services life.

Aili warehouse: Aili warehouse is covering an area of 20000 sqm, has more than 3000 items and normally have 2000tons to meet customers’ fast delivery. Main products are bucket teeth,bucket adapter, bucket side cutter, bucket pin, bushing and so on.

COMPANY OVERVIEW

Located in the beautiful Yichun City Jiangxi province, near in Ningbo port and shanghai port. Aili is a modern enterprise specialized in the R&D, manufacture and sales of precision casting parts. Aili established in 1980,we already have 40years casting experience .Covering an area of 110,000 sqm; have more than 200 staffs; Annual production capacity is 24,000 tons; Export to all of world more than 100 countries; Annual Sales Volume more than 30 million dollars among it ,60% is overseas market, 40% is domestic market.

Our company has advanced investment casting line, forging line, environment friendly continu-ous heat treatment furnace, as well as the top testing equip-ment in this industry. Now we mainly supply all kinds of excavator bucket, bucke tteeth & adapters and some precision casting &forging products, like:Teeth,Adapter,side cutter,cutting edge,bucket,protector,pin,retainer,bolt,nut ect We can develop and design all kinds of mould, precisioncasting mould and forging upon special request.

Trade mark: Aili

AIli possessing precisionfoundry factory, Ceramics Casting factory,Automatic production line we also can call Static pressure modeling line (SPML )Aili is also the only manufacturer in China that use static pressure line to produce tooth and adapter,precision forging factory, mold and CNCmachining center  TESTING EQUIPMENT

TESTING EQUIPMENT

We have most advanced physicochemical inspection equip-ment including: Optical Spectrum Analyzer which inspect and analyze chemical composition, Metallography microscope which testing the Inspection Machinery:We have 6 sets Wire cutting machine,Improve the speed of mechanical performance test Rockwell Hardness Tester and Brinell hardness tester to test the block,These two machines can provide customers with different reference hardness requirements. our Impact Testing Instrument ,Tensile testing machine to test the thoughness and tension.

Advantages

1.Cooperating with world famous brands ,

1.to be the supplier of VOLVO since 2014

2. to be the supplier of the world’s first brand of loader SDLG in 2018 .

2.Certificate of Design Patent ,we got this in 2016. 3.Aili is the only company in China that can independently develop chemical composition materials. INDEPENDENT RESEARCH AND DEVEL OPMENT, Our company has independent R & D department, whichspecialized in developing new products.

4 We have got 8 invention patents Meanwhile our company has been confimedas National Hi-tech enterprise.

5.warehouse with more than 20 thousand spuare meters , can stock about 3000 tons products in it. Export goods are all packed with MDF wooden case and we will put a water-proof plastic inside to prevent rust during shipment on the sea.

112我瞧瞧

Q1. Sample

—- sample is free,but you need to pay the freight.

Q2. Address

—- Factory Address: NO.1, CENTURY AVENUE,INDUSTRIAL PARK, JING’AN COUNTY, YICHUN CITY,JIANGXI P.R., CHINA

Q3. Product

—- Teeth,Adapter,side cutter,cutting edge,bucket,protector,pin,retainer,bolt,nut ect

Q4: Paymment Terms

—- T/T

Q5. Logo

—- No logo/Aili/Customized.

Q6. Lead Time

—- Products in stock: immediately; Regular products: 20 days.

Q7. Aftermarket

—- We guarantee the product quality. If there is any problem, we have a professional service team to reply within 24 hours and provide solutions within 3 days.